This construction method statement details general PT slab procedure to follow for Post Tension Works for slabs at any kind of civil construction project.

PT slab method of statement covers the works of the post tension from placing of the ducts to the final stressing and grouting.

Separate method statements are available for the works of formwork, reinforcement and concreting.

Below is the sequence of activities as per this method statement.

Formwork

Installation of the post tension ducts

Installation of the reinforcements

Installation of the conduits for electrical services and sleeves & openings for the other MEP services

Concreting

Stressing

Grouting

Curing

HSE General Requirements

The entire post tension works will be carried out as per the guidelines established in the project specific HSE plan.

Utmost importance shall be given to safety of personnel and protection of existing above /underground Services.

It will be ensured that the personnel involved are thoroughly aware of the “Contractor”/ Employer Safety regulations.

To achieve the above the following shall also be ensured:

Tool Box Meetings will be conducted before starting the pt slab works.

All personnel will be provided with suitable Personal Protective Equipment.

Site staff to make sure that people use the necessary PPE’s while working at height and edges.

Required permits will be obtained from the Engineer/ authorities concerned before starting the works.

Plant & Equipment’s shall be fully tested & certified by an independent testing agency. Copies of certificates shall be submitted to Engineer

All pneumatic / lifting equipment’s including booms, slings; chain blocks etc. shall be fully tested & certified by an independent testing agency. Copies of certificates shall be available.

The area must be clearly barricaded and sign boards must be fixed not to allow movement of people and traffic.

People should not be allowed to work in the area where stressing jobs are in progress.

Site Engineer/Supervisors must make sure that necessary platforms are available for the people to perform stressing jobs prior to starting the job.

All people must be properly trained prior to starting jobs and all hazards must be conveyed to them by the way of Tool Box meeting.

Jacks used for the job must be of good quality. Test certificate shall be available.

Site staff must make sure that excess pressure is not exerted during the stressing jobs that could lead to breakage of strands/tendons/bananas.

Necessary Manpower

Post Tension Coordinator

Masons

Site Engineer

Steel Fixer

Supervisor

Helpers (skilled, semi-skilled)

Post Tension Technician

Mandatory Equipment & Materials

- Transit Mixers

- Thermometer

- Concrete Pump

- Mono strand stressing Jack

- Water Tanks

- Hydraulic Pump

- Air Compressor

- Bulb (onion) Dead end jack

- Mechanical Vibrator

- Grout pump

- Masonry tools (trowels & hand tools)

- Theodolite /Total station

- Wheel Barrows

- Dumpy Level

- Cube Moulds

- Water Level

- Tamping Rod

- Spirit Level, Right Angle, Plumb Bob

- Slump Cone

- Hammer

- Formwork material (ply board, soft wood, nails, Tie Rods, Clamps)

- Mould Release Oil

- 7 wire strand for pre-stressed concrete size 12.7 mm/low relocation/Grade 270K.

- Anchor head SF305, 405 & 505 (Epoxy coated)

- Wedge 0.5” through cargo EX, apollan

- Pocket former SF305, 405 &505

- Corrugated galvanized metal flat duct for tendon 305 & 405 with 5.8M length per piece.

- Corrugated galvanized metal flat duct for tendon 505 with 5.8m length per piece.

- Non Shrinkage grout

- Polythene Sheet / Hessian Cloth

- Concrete as per specifications

- Concrete Repair materials.

Roles & Responsibilities for Post Tension Work

Project Manager has the overall responsibility for the implementation of this pt slab method statement. He shall ensure that the approved Supplier for Ready Mix Concrete/Independent Testing Agency and Sub-Contractors as well other team members are aware of the requirements of this method of statement.

Project Manager is responsible to coordinate with the company legal coordinator and the local bodies for obtaining necessary and essential work permits – if any, for proceeding with the works.

Construction Manager/ Project Engineer will ensure that the resources are available to carry out the post tension works as per the schedule.

The Project Engineer/Site Engineer is responsible to carry out the works as per Shop Drawings, specifications and relevant method statements for each civil construction activity.

Form Works for PT Slab

Form works shall be designed and constructed in accordance with applicable codes within the specified tolerances to the shape, lines, and dimension required by the design drawings(s).

Forms shall be coated with mould oil or suitable release agent.

For slab work, Shore/ support shall be provided for floor directly under slab being placed so that loads from construction above will safely transfer directly to these shores.

Formwork shall be struck without damaging, disturbing, or overloading the structure. This shall be done after applying the final stress in the slab and shall be agreed with the consultant engineer.

Calculations for formwork shall be submitted for consultant approval.

Reinforcing Steel Work

Re-bar work shall be performed in accordance with the relevant specifications, drawings and as per the Bar Bending Schedule.

Copy of mill certificate of the consignment shall be submitted to Engineer upon receipt of Rebars at site.

Where it needs, store the rebars under cover on timber or concrete blocks at a minimum height of 300 mm above ground.

Binding of rebar shall be done using annealed wire of 1.6 mm dia. (16 gauge).

The concrete cover to the reinforcement shall be as per approved drawings.

The lap length of rebar shall be as per drawings and project civil works specifications.

Reinforcement shall be securely fixed in position within a dimensional tolerance of 20 mm in any direction parallel to a concrete face and within a tolerance of 5mm at right angles to a face, provided that cover is not thereby decreased below the minimum specified or otherwise as shown on drawings.

Embedded Items

Anchor bolts, pipe sleeves, Conduits for electrical works, drains, curb and trench angles, and other inserts as shown on the design drawings shall be placed, secured, and protected during placement of concrete.

Engineers of relevant discipline from the subcontractor side shall check installation of embedments related to their scope of work.

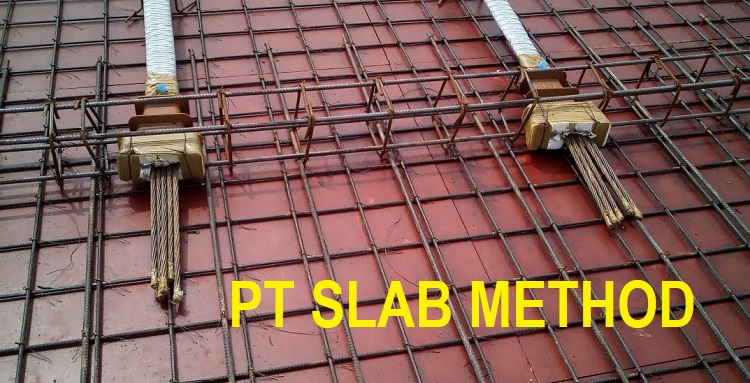

Standard work method of Post Tensioning (Multi strand flat duct, bonded system)

Tendon Installation – Set up of pre-stressing tendon components

Uncoil and lay strand in position.

Lay duct into position and connect ducts with duct couplings (Minimum vertical tolerance of duct positioning to be +/- 5 mm & minimum concrete cover to all ducts to be 25 mm).

Insert or push the strand into the duct with one strand at a time.

Set up bar chairs and profile according to the location given on drawing.

Tape all duct joints.

All tendons should be placed in the location and profile as shown by drawing.

Set up of stressing anchorage components.

Set up slab edge formwork and stressing recess on slab edge formwork.

Install anchorage bearing plate to stressing recess formwork.

Support and fix the anchorage bearing plate into position using chair.

Provide and fix grout vent.

Provide and fix anchorage bursting reinforcement.

Seal all connections of components with tape.

Set up of “Dead End (DE)” anchorage components.

The onion (bulb) dead end type will be used.

The strand for each tendon will be formed with onion dead end by means of a special hydraulic jack.

Anchorage bursting reinforcement at DE will be fixed into position as shown on attached DE details.

Concrete Pouring for Post Tension Works

Pouring concrete shall be done when the mild steel reinforcement and post tensioning components are completely installed.

Should construction joints be needed during the pour, joints shall be located on drawing.

Tendon shall be observed during concreting. Any misalignment of tendon shall be rectified.

After concreting is complete the concrete should be cured as appropriate until the specified strength has been attained prior to stressing operation.

Cube sampled shall be a minimum of 1 set (7 cubes) for each 75 cum. and thereof of each concrete placed in any one day. Of which 3 cubes shall be tested for 7 days and 3 for 28 days compressive strength. 1 cube shall be retained as reserve for later testing.

Additional 15 cubes/slab shall be taken and set of 3 cubes shall be tested at 24 hours interval for monitoring the concrete strength to apply the initial and final stress.

PT Stressing Procedure

Take off side formwork and stressing recess formwork prior to stressing operation

Clean up strand prior to stressing operation

Color mark strand for elongation measurement reference

Place anchor head and wedge into each strand

Commence pt stressing after concrete has attained the specified compressive strength.

Stressing load on each strand should be as specified prior to lock off.

Stressing should be done according to sequence given. The tendon should be stressed from one end only except otherwise indicated on the drawings.

Stressing can be performed in both directions (transverse and longitudinal tendon) at the same time if specified.

Elongation should be observed and recorded as soon as the stressing is complete.

Stressing equipment’s i.e. jack and pump should be set at a given operating

Pressure as conformation to the calibration document.

The elongation as measured should be verified with theoretically calculated Elongation, as submitted.

The discrepancies if any should be rectified satisfactorily.

After the elongation has been approved the strand should be cut using the abrasive disc.

Grouting

Grouting should be performed as soon as the stressing operation is complete.

Grout vents are provided at anchorage for each cable.

The anchorage should be capped with concrete or suitable capping material prior to grouting operation.

As soon as flushing is completed the grout operation shall start.

O.P Cementitious Grout mix shall have the mix proportion of water/cement ratio as specified by the weight.

Typical properties of grout mix are as follows:

Water / cement ratio ≤ 0.49 by weight.

After grouting complete the projected projection of grout vent shall be cut flat by the means of abrasive disc.