DESCRIPTION OF WORK

This specification covers all sound & vibration isolators for mechanical equipment to prevent the transmission of vibration and mechanically transmitted sound to the building structure.

It also includes adjusting each mounting system, and measurement of isolator system performance when so requested by the Consultant.

Specific mounting arrangements for each item of mechanical equipment shall be as described herein. However, the mounting arrangements specified are to be considered as the minimum requirement.

It is the Contractor’s responsibility to ensure that the vibration isolation equipment is selected in accordance with the type of construction (i.e. the building structure) and the vibration/noise generated by the selected equipment.

Contractor shall include for all necessary items required to ensure that the specified noise criteria is achieved.

The contractor shall be responsible for proper selection and adjustment of the operation of the MEP systems and equipment, meeting the specified design noise criteria, and limiting vibration levels to the ”imperceptible” zone on the Reiher-Meister Scale.

The above requirements are essential for all occupied areas other than plant rooms but also are required wherever the unfavorable noise and vibration levels could conceivably cause damage to structures or services.

The contractor shall employ an approved Acoustic Consultant to ensure and implement appropriate noise and vibration control systems and elements.

Subsequently contractor shall submit for approval noise and vibration calculations produced by the Acoustic Consultant together with other related submittals for acoustic and vibration suppressing materials.

Noise Level Control

Adequately isolate all equipment to maintain acceptable noise levels in the occupied areas of the building as specified below. Take noise measurements over the complete audible frequency range in each of the occupied zones under, above and beside mechanical equipment rooms and where indicated by the Consultant Submit a report, complete with resultant sound curves to the Consultant substantiating that all equipment has been adequately isolated and that acceptable noise levels exist in the occupied zones. Refer to the following acceptable NC levels:

Noise Levels (Maximum)

| Area | NC Level

(Maximum) |

| Class rooms/science lab | 30 |

| Sport hall/auxiliary gymnasium | 40 |

| Auditorium | 25 |

| Library | 30 |

| Swimming pool | 40 |

| Cafeteria (seating area) | 40 |

| Kitchen | 50 |

| Corridors | 30 |

| Administration offices, staff rooms | 30 |

Manufacturer’s Qualifications:

Firms regularly engaged in manufacture of sound attenuators and vibration isolation products with characteristics, sizes, and capacities required, whose products have been in satisfactory use in similar service for not less than 5 years.

Product Data:

Submit manufacturer’s technical product sheet including performance data for each size and type of sound attenuator and vibration isolator furnished; schedule showing drawing designation, room location, number furnished, model number, size, and accessories furnished; and installation instruction.

Shop Drawings: Submit assembly-type shop drawings indicating dimensions, weight loadings, required clearances, and methods of assembly of components.

Maintenance Data: Submit maintenance data and parts list for each type of sound attenuator and vibration isolator including “trouble shooting” maintenance guide. Include this data, product data, shop drawings, in maintenance manuals.

DELIVERY, STORAGE AND HANDLING

Deliver sound attenuators and vibration isolator with identification on outside of casings indicating location to be installed.

Avoid crushing or bending, and prevent dirt and debris from entering and settling in sound attenuators and vibration isolators.

Store material so as to protect from weather and construction work traffic. Where possible, store indoors; when necessary to store outdoors, store above grade and enclose with waterproof wrapping.

MATERIALS

All vibration isolation devices, factory built silencers and acoustic plenums shall be provided by an approved manufacturer.

Vibration isolation devices shall be restrained against excessive movement during a seismic event by the use of resilient snub. Design shall meet the requirements of seismic zone 1.

Factory-Built Silencers:

All silencers shall be completely pre-fabricated of noncombustible materials and shall have a minimum insertion loss to suit equipment and required terminal noise levels and a maximum air pressure drop of 62 pa.

Acoustic media shall be packed under compression and protected from air erosion by minimum 22 U.S. ga. perforated galvanized sheet metal.

Silencers with internal air velocities above 22.86 m/s shall have acoustic media additionally protected from erosion by glass fiber cloth.

The silencers shall have 50 mm slip connections unless specified otherwise.

Silencers shall be painted with anti-rust prime coat. Supply lifting lugs on units with cross sectional dimensions larger than 600 mm.

Class 1 silencers of rectangular construction shall have an outer shell of 22 U.S. ga. minimum galvanized sheet metal and shall be used in ductwork not in excess of 1000 Pa or the design pressure of the silencer, whichever is lower.

Class 2 silencers of rectangular construction shall have an outer sheet of 16 U.S. ga. galvanized sheet metal, with continuous welded seams and painted with one anti-rust prime coat. Splitter shall be reinforced with formed channels. End connections shall be steel galvanized angle flanges. They shall be used in ducts over 1000 Pa or where Class 1 silencers cannot be used.

Circular silencers shall be all welded construction with a minimum 16 U.S. ga. galvanized sheet metal outer shell and 22 U.S. ga. perforated galvanized sheet metal inner shell for diameter over 600 mm. For smaller sizes 18 U.S. ga. and 24 U.S. ga. respectively shall be acceptable.

Submit certified data of pressure drop, insertion loss and generated noise of silencers. Data shall be certified by a qualified independent testing laboratory.

The insertion loss shall consist of sound pressure level in the diffuse sound field of a reverberant room where a silencer is substituted for the same length of empty duct and the rest of the system unchanged.

The test method used by the independent testing laboratory certifying the silencer data, shall be fully described.

The certification of the pressure drop, insertion loss and generated noise data shall be based upon tests of the same silencer for all measurements.

Provide silencers as required to achieve noise levels specified.

Vibration Isolators

All steel spring isolators should include a neoprene pad at least 10mm thick mounted next to and in series with the spring.

The neoprene used in isolation (unless otherwise stated) should have a durometer between 30 and 70.

All rubber isolators should be double acting with no through-bolted connections.

There shall be at least a 50mm air space between the bottom of the isolated equipment and the floor slab.

INSTALLATION METHOD STATEMENT

Ceiling Suspended Fans:

All fan hangers shall have static deflections equal to or larger than 20mm.

Each fan shall be suspended by means of spring hangers consisting of a steel housing or retainer incorporating a steel spring and neoprene-in-shear.

If the fan to be suspended is not furnished with integral structural frame and external mounting lugs of suitable strength and rigidity, install approved structural base with lugs in the field.

Vertical fans shall have similar arrangement except fans shall be supported off walls.

Support of Piping:-

- Suspend all piping in mechanical rooms and all piping larger than 75mm Φ on resilient hangers. Resilient supports shall be steel spring and neoprene-in-shear isolators with static deflections equal to or larger than 25mm.

- For piping connected to vibration isolated equipment, pipe supports within 10 pipe diameters of the equipment shall have a static deflection of twice the deflection of the vibration isolated equipment. All other piping supports shall have a static deflection of 25mm minimum.

- Penetrations of walls or floors should allow for a 25mm clearance around the pipe.

- The gap should be stuffed with glass fiber insulation and sealed with non-hardening caulking.

- The pipe should not be allowed to rest on the side of the hole.

Floor-Mounted Centrifugal Pumps

Mount each pump with motor on a spring supported steel and concrete inertia base reinforced if necessary, of thickness as follows:

Pumps up to 5 hp – 150mm

Pumps 7 ½ to 25 hp – 250mm

Each base for horizontally split pumps shall include supports for base elbows for the discharge and suction connections and in case of vertically split pumps shall include only support for base elbow for suction connecting bolt and grout base elbows to the steel and concrete pump base.

Mount the steel and concrete base on spring mountings.

Where the concrete base is ‘T’ shaped or other than rectangular, locate the spring mountings under the projections as well as the main body of the base.

Spring mountings shall be self-contained concrete inserts with flush openings on the side of the base for spring adjustment or removal.

Pour bases on roofing felt and elevate 50mm with mounting adjustment bolts after the pumps are grouted to the base.

No damping or snubbing materials shall be used.

Spring deflection shall be at least 25mm and all mountings shall have 6mm thick neoprene vibration isolation pads at the bottom.

Pump and motor shall be in one-piece base.

Base of two or more sections welded or bolted together is not acceptable.

Slab-on-grade or Basement Floor-Mounted Centrifugal Pumps:

Bolt and grout each pump to a steel and concrete base supported on 25mm thick neoprene-steel- neoprene pads.

The neoprene-steel-neoprene pads shall be in accordance with the manufacturer’s instructions for the size and weight distribution of the pump supported.

The minimum concrete base thickness shall be:

Pumps less than 5 hp – 150mm

Pumps 7 ½ to 25 hp – 200mm

Air Handling Units: The unit should be isolated from the structural slab by spring mounts with a static deflection of at least 50mm.

Fan Coil Units and fans: The units should be isolated from the building structure with steel spring mounts with a static deflection of at least 25mm.

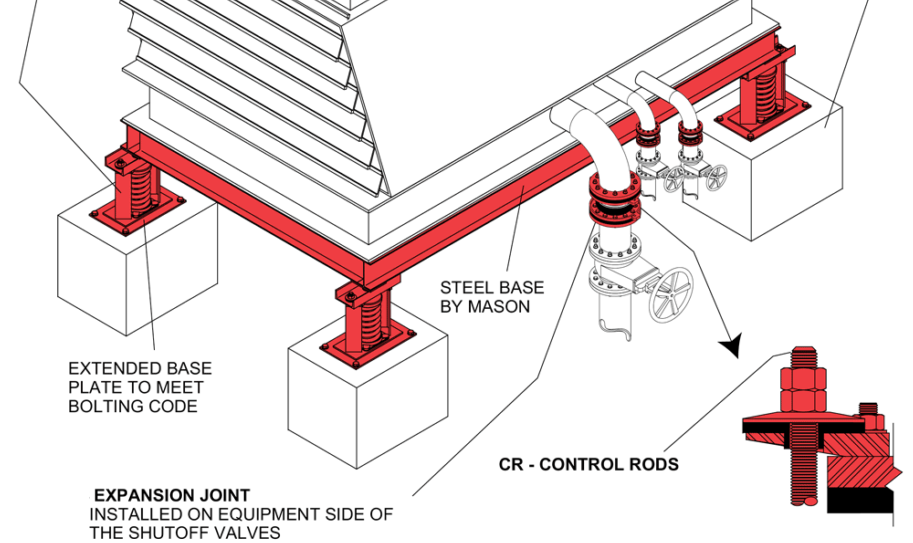

Chiller Units: The chiller units should be mounted on steel spring mounts with a static deflection of at least 75mm. The spring isolators are to rest on pedestals mounted directly on the structural base.

PIPING/ELECTRICAL CONNECTIONS TO MECHANICAL EQUIPMENT

All electrical connections should be made via flexible cable with enough length to create a slack, looped connection.

Piping connections to equipment should incorporate flexible rubber expansion joints close to the equipment.

The first three pipe supports outside the expansion joints should incorporate steel spring isolators with a static deflection of at least equal to the equipment isolator static deflection.

First three isolators should be of the pre-compressed type to avoid excessive loading on the piping.

Within the mechanical equipment room, or to a radius of 15m from the equipment (whichever is greater), the piping should be supported on steel spring isolators with a static deflection of at least 25mm.

Any piping over 75mm in diameter located outside the mechanical equipment room should be supported with steel spring isolators with a static deflection of at least 25mm.

In general, piping hangers should be attached to structurally stiff portions of the buildings.

Vibration isolation hangers should be installed with the spring as close to the ceiling as possible.