Instructions for the implementation of this SWMS:

- Review the SWMS on site with the relevant employees and contractors.

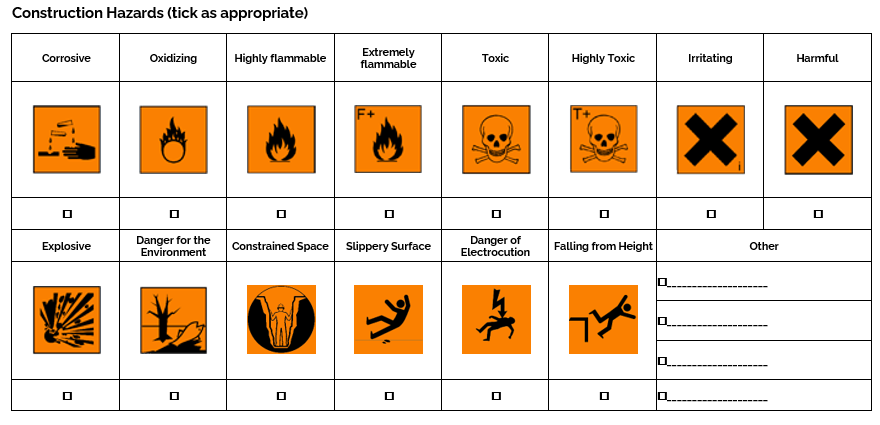

- Identify and document the high risk Construction Work to be performed.

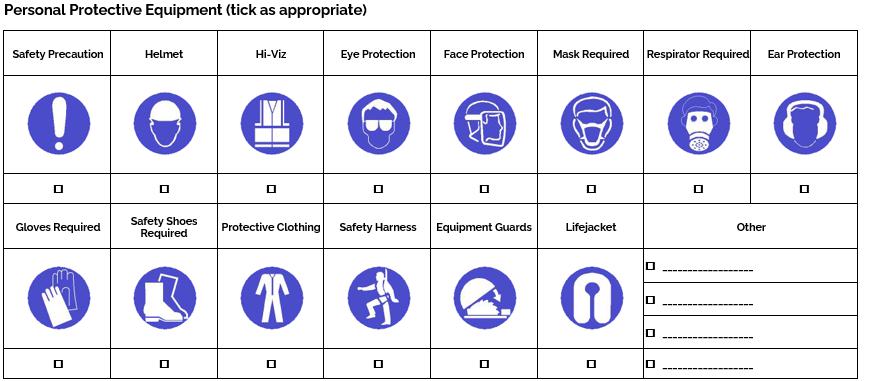

- Identify and document the site PPE requirements for the task.

- Document any additional work methods, tasks and hazards identified on site and the control measures required to mitigate the associated risks.

- Each team member to sign onto the SWMS before starting the work.

- Team members to stop work immediately if the swms cannot be complied with.

- Observe work being performed and in case controls are inadequate, stop the work, review the SWMS, implement additional controls and re-brief the team.

- Sign onto the amended SWMS before recommencing after any SWMS revision.

Tick from Below High Risk Construction Work, that are involved in this SWMS:

| Where there is a risk of a person falling more than 2 meters | On or near pressurized gas distribution mains or piping | ||

| Work on telecommunications towers | On or near chemical, fuel or refrigerant lines | ||

| Involving demolition works | On or near energized electrical installations or services | ||

| Involving the removal or likely disturbance of asbestos | In an area that may have a contaminated or flammable atmosphere | ||

| Involving structural alterations that require temporary support to prevent collapse | On or adjacent to roadways or railways used by road or rail traffic | ||

| Involving a confined space | Involving tilt-up or precast concrete | ||

| Involving a trench or shaft if the excavated depth is more than 1.5 meters | At workplaces where there is any movement of powered mobile plant | ||

| Involving a tunnel | In an area where there are artificial extremes of temperature | ||

| Involving the use of explosives | In over or adjacent to water or other liquids where there is a risk of drowning |

Risk Control

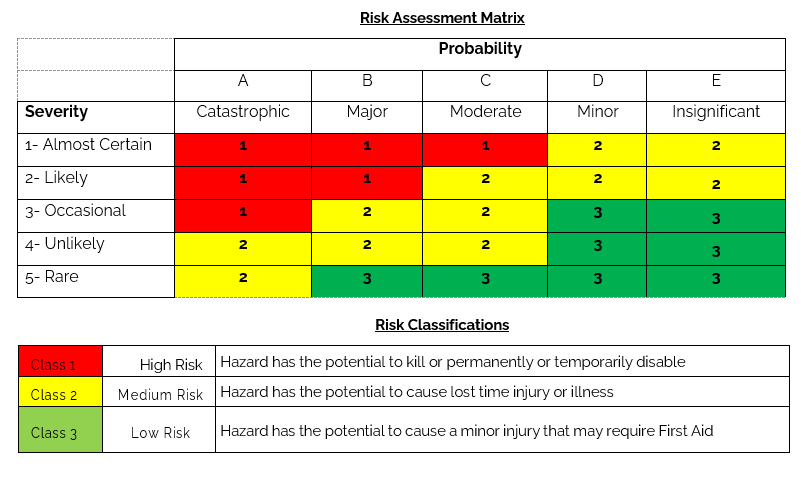

Identify the control options and choose the control measure that is as close to level 1 as is reasonably practicable.

1.Eliminate any risk to health or safety associated with the work such as isolate and lock out the energy at its source.

2.Reduce the risk to health or safety by any one or any combination of the following:

- Substituting a new activity, procedure, plant, process or substance

- Isolating persons from the hazard, such as barricading, fencing or guard railing, or

- Using engineering controls, such as lifting devices.

3.Use administrative controls, such as changing the way the work is done.

4.Provide appropriate personal protective equipment.

Work Method / Task Description |

Hazard Identification |

Risk Level |

Actions / Controls for Prevention |

Residual Risk |

Responsible Person |

| 1. Inspect work area and review SWMS on site | Site specific hazards |

3 |

Document site specific hazards and control measures |

3 |

Supervisor/ Worker |

| 2. Check layout and mark out. |

Sun exposure

Slips, trips & falls |

2

3 |

Wear long sleeves shirt and hat.

Apply sunscreen to exposed skin. Ensure adequate water available. Regular rest breaks during periods of extreme sun exposure. Ensure work areas, in particular, walkways are clear of tripping hazards |

3

3 |

Supervisor/ Worker

Supervisor/ Worker |

| 3. Install disposable lids for conduit boxes to timber | Walking on unstable reinforcing steel |

2 |

Use kneel boards or walkways |

3 |

Worker |

| 4. Lay conduit and accessories. | Cuts & abrasions.

Chemical glues |

3 3 |

Wear gloves for hand protection

Refer to Conduit glue MSDS for correct chemical handling requirements |

3 3 |

Worker

Worker |

| 5. Tie down conduit. | Cuts & abrasions |

3 |

Wear gloves for hand protection |

3 |

Worker |

| Additional items identified on site | Supervisor/ Worker |

| Personnel Qualifications and Experience Required | Personnel Duties and Responsibilities | Training Required to Complete Work |

| Minimum of Electrical Worker Grade 3 or apprentice working under the effective supervision of a qualified Electrical Worker minimum Grade 5 | Supervisor to carry out daily inspections of work site for hazards | Supervisor to be trained in hazard identification, risk assessment and control eg, SWMS |

| Industry and Site induction | All personnel to maintain tidy work area on site at all times. Personal Protective Equipment (PPE) to be worn at all times on site | Supervisor to be appropriately trained, qualified and competent in OH&S and electrical practices for the task |

| No previous particular experience required | On the job skills training to be conducted by Supervisor to personnel. | |

| Engineering Details / Certificates / WorkCover Approvals / Australian Standards | Referenced – Codes of Practice / Regulations / Legislation | |

| To Local applicable standards and client specifications

All PPE used to meet & be maintained to local standards |

Occupational Health and Safety Act, Occupational Health and Safety Regulations, Electricity Safety Act, Electricity Safety (Installations) Regulations, Industry Standard for Electrical Installations on Construction Sites – Safe work on LV electrical installations | |

| Plant / Equipment Required (Mobile or Static) | Maintenance Checks / Calibration Intervals | |

| None | Hand tools to be checked daily | |

Worker Sign On

I the undersigned have been consulted on the development and implementation of this Safe Work Method Statement, SWMS – CONDUIT INSTALLATION PRIOR TO POURING CONCRETE, and I have read and understood the SWMS and agree to work to the requirements of this Safe Work Method Statement.

| Name | Signature | Date | Rev No. | Initial | Date | Rev No. | Initial | Date | Rev No. | Initial | Date | Rev No. |