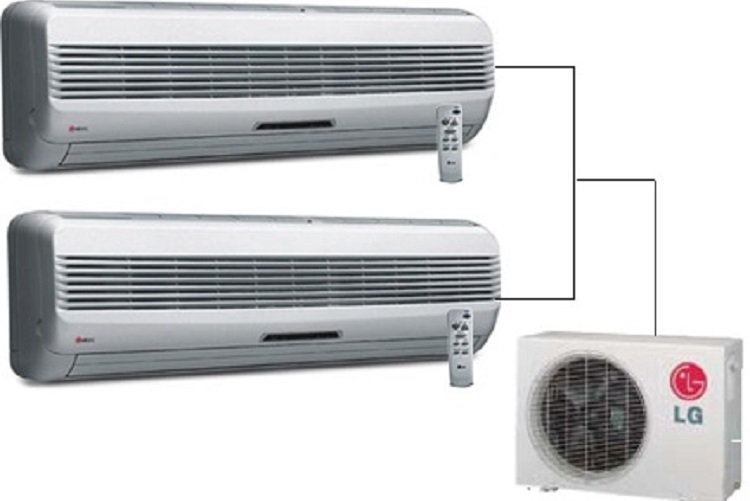

Below is given major sections of a safe work method of statement for Testing & Commissioning of DX Split Units. This is a normal procedure for doing testing activity. All method statement can be called safe work method statements once we attach

Read Full Method Statement

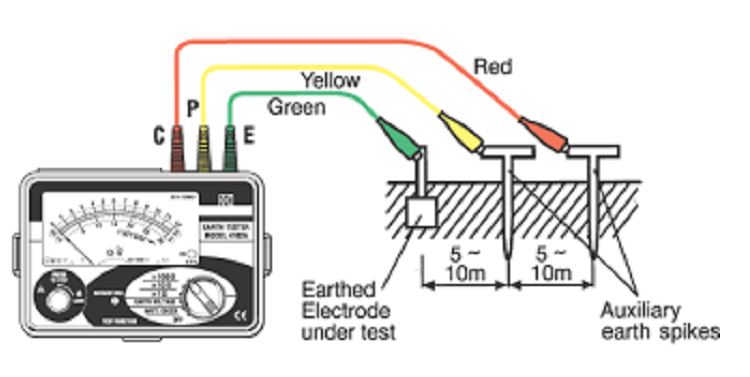

Purpose of this electrical procedure is to define the step by step method to implement the correct practices for the installation pre-commissioning & commissioning of electrical earthing system. Guidelines contained herein shall ensure that the job execution complies with the project requirements

Read Full Method Statement

This procedure covers installation & testing of access control system including readers, reader interfaces and accessories, to ensure the required quality control activities are done as per project specifications and client requirements. Method statement details the activities, procedure to follow, specialized tooling

Read Full Method Statement

This method statement describes the procedure for installation of above ground drainage piping system. Document applies to the inward site inspection, installation and inspection methods to be adopted for the above ground drainage piping system. Project manager is overall responsible for the

Read Full Method Statement

This safework procedure helps to provide guidance in carrying out the necessary measures to avoid flooding during testing and commissioning activities at the construction project. Purpose of this method statement is to control the water flooding that may occur during commissioning activities.

Read Full Method Statement