You can find below a very precise and useful method statement for the cleaning of HVAC ducting system including steel and any other metallic air ducts.

Following tools are required for the cleaning of GI ducts for HVAC Systems which should be arranged before starting the cleaning of ducting works on any type of project.

- Cleaning Tools

- Vacuum Equipment and accessories

- Ladders/ scaffolding

- Manometer for air checking

- Air Compressor

- Retractable Fall Arrester System

- Safety Breathing apparatus or (SCBA)

Preparatory Procedure for Cleaning HVAC Ducts

Prior to commencement of work, coordination will be done with other MEP services on the project or building.

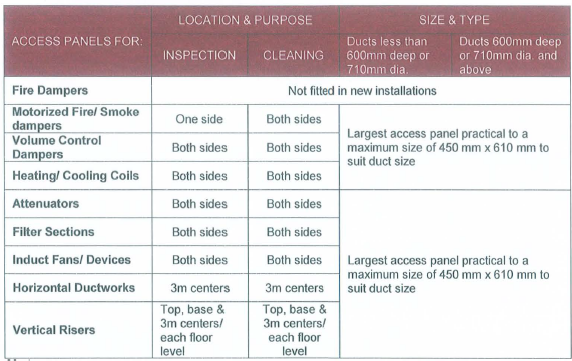

Ensure access panel are widely open for the insertion of tools some access panels can be used near VCD, Fire dampers, filter sections horizontal duct works etc. refer to as build drawings of the building to locate access panels and sizes chart.

Conduct a pre inspection to determine exact location and type of AC equipment and to understand what kind of access points are required.

Make sure that the AC system is working smoothly and there is no abnormality of sound or noise before starting the duct cleaning work, if there is any such unusual noise report shall be submitted to the building operation management or tenancy maintenance before conducting the cleaning.

HVAC Duct Cleaning Procedure

Close AC system or isolate a section of ducting which needs to be cleaned.

Place protection on furnishings or equipment below the areas.

Create negative pressure by using specialized vacuum equipment installed either inside the building with HEPA filtration or outside the building using the primary filtration or monster vac.

Remove grills / vents and plug openings except for the one farther away from the vacuum equipment.

From the vent / grill farther away, insert the selected cleaning tools used to loosen the dust dirt and debris, which shall be pulled away inside the ducts while working toward the vacuum containment equipment.

For longer horizontal distance ducts, tools for cleaning shall have extended arm to reach the point where to remove dust dirt’s and debris manually be sure no solid and sharp objects left before using the vacuum equipment.

Use Plastic sheeting on the ground while transferring or mixing cleaning chemicals as required by specialist and manufacturers standard.

When sections of supply or return air ducts have been completed sanitizing shall be carried out using sanitizer.

All the filters, grills, coils and drip trays shall be cleaned and sanitized.

For vertical and riser ducts locate the access door panels, and use selected tools for cleaning and removing dirt dust and debris if found inside the duct works before using the vacuum equipment.

Access points and locations of access doors and panels are provided below as a sample, which are installed on the system in accordance with approved shop drawings and specifications.

Important Instructions for AC Air Duct Cleaning

Patented access doors may be put forward for acceptance.

Short flanged/removable duct sections to be used where the access panel would be less than 300mm x 200mm.

For large ducts requiring ‘man access’ the largest access panel available shall be used.

Where man access’ is provided within vertical risers a suitable fixing for a safety harness shall be provided adjacent to the access panel.

Access panels shall be positioned within 1 meter of the item to be cleaned.

For large duct cleaning acquire a person to go inside for cleaning but make sure that the use of breathing apparatus and limit the maximum time duration 15-20 minutes to stay inside the ducts to avoid suffocation or any accident.

During the process of cleaning the hvac ducts aside from using SCBA appropriate ventilation hoods must be placed inside the ducts access opening where the blower fan discharges air inside the large ducts and also after cleaning manually start using the vacuum equipment to suck all fumes left during cleaning.

Close access panel or access doors instantly after finishing the process of duct cleaning.

Ensure all ducting systems are completely clean, provide signed reports and forward to the client/consultant, the inspection of duct cleaning works shall be witnessed by manufacturer representative and in compliance with the testing & commissioning plans and schedules where applicable.

Discover more from

Subscribe to get the latest posts to your email.