Pre-Commissioning Procedure for VAVs / CAVs

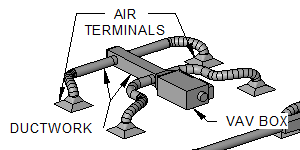

Ensure that the VAVs / CAVs installation is complete & mechanical completion is approved. Ensure that the VAVs with 12 point flow cross type of averaging air flow sensor installed as per approved drawings.

Ensure that no damage occurs between mechanical completion & pre-commissioning. Ensure that proper access is available for VAVs & CAVs. Repair all damages to the equipment galvanizing finish.

Check VAVs / CAVs are installed as per the approved shop drawings and manufacturer’s instructions. Check the sensing grids tubing connection from the grids to the transducer is correct & secure.

- Check for proper mounting of the actuator on the body of the VAV / CAV.

- Check that the thermostats as per approved material submittal are fixed.

- Check duct connections and grilles as per approved shop drawing and respective method statement & are cleaned internally & externally.

- Check all VCDs, BDs and fire dampers are open.

- Check for proper electrical power, control and earthing connections as per manufacturer’s recommendations. Field wiring to be pre-tested for continuity and insulation resistance.

- Ensure that VAVs & CAVs are interfaced with the BMS system.

- Ensure the precommissioning & commissioning of AHUs is complete in line with the approved procedure.

- Check & ensure that the thermostat LCD display features are in line with the approved material submittal.

Commissioning Procedure for VAVs / CAVs

- Ensure that all the precommissioning checks are carried out successfully.

- Ensure that the AHU is operating & sufficient air flow is obtained at the suction of the VAV/CAV.

- Check for proper suction & discharge of air through the VAV / CAV.

- Change the thermostat setting & check for the modulation of the damper in the VAV/CAV.

- Check for proper operation of the actuators.

- Check the entry of air through the induction port using a rotating vane anemometer.

- Measure & record the value due to changes in the thermostat setting in form.

- Check for any undue vibrations / noise.

- Complete air balancing of the entire HVAC system shall be carried out in line with the approved procedure.

- During air balancing the VAV flow rate shall also be measured & recorded in the performance record sheet.

Discover more from

Subscribe to get the latest posts sent to your email.