The sub-contractor doing the upper floor wall frames installation is responsible for carrying out particular actions, as listed in this risk assessment document, complying the control measures.

Supervisor is responsible to ensure that the sub-contractor is competent and satisfied with the procedures listed.

The supervisor is required to provide supervision, to the extent necessary, to make sure the Safe Work Method Statement is being followed and to take immediate corrective action as per site conditions.

Job Step: Assess access and upper floor level area

Identified Hazard and Risk Assessment: Slips, trips, falls, unsecured/unstable ladders/steps or ramps

Control Measures:

1. Before ascending to the first floor level ensure fall protection at floor perimeter and stair void is in place, all ground floor temporary bracing is adequate and secured to take the additional loads and that ‘no-go zones’ are in place in areas where objects could fall from the 1st floor deck.

2. Secure ladder access to first floor ensuring that ladders are secured at the top and bottom.

3. Clear/secure items that have potential for slips/trips etc. and remove items that may obstruct erection of frames

Job Step: Unstrap frames from bundle

Identified Hazard and Risk Assessment: Crushing, falling objects, cuts from straps

Control Measures:

1. Ensure frames will not slide or fall when straps are cut (note: use tin snips or strap cutters for task)

2. Straps should be cut so that they are prevented from striking the body when tension is suddenly released. Straps should be placed in waste enclosure immediately

Job Step: Carry frames to upper floor level

Identified Hazard and Risk Assessment: Slips, trips, sprains and strains

Control Measures:

1. Assess the path (clear rubble, fill or bridge holes). Use original platform that was used for the installation of floor sheeting. Adjust edge protection to provide sufficient access to allow frames to be passed up to the floor deck. Note: Edge protection must be reinstated after wall frames have been passed up.

2. Assess the weight of frames (there is a high risk where a lifted weight exceeds 20 kg. per person). A 2.4m high wall frame of radiata pine weighs approximately 11 kg. per lineal meter. If frames are too heavy for manual handling deploy mechanical means of lifting (ie. crane)

3. If frames can be safely handled manually, persons handling the frames should lift frames using correct lifting techniques (keeping back straight). Frames should be carried by the studs so that the frames will be in the correct position (plates at top and bottom) when placed against the side of the house.

4. Hand frames up to persons above on upper floor level.

5. Persons on top deck must stay 500mm back from edge as those on ground lift and tilt frames towards them.

6. Persons on the upper floor level must hold the top section of the frames, pull them back towards the centre of the upper floor and lay them flat.

Job Step: Carrying and standing frames

Identified Hazard and Risk Assessment: Persons and objects falling, frames over-balancing, sprains and strains, slips and trips

Control Measures:

1. Allocate one person to attend to the temporary braces which should be ready before standing commences (there must be two braces per frame).

Allocate duties (minimum 3 persons per section of frame, 2 persons to carry and stand, the other to attend the temporary braces).

2. Stand frame part way to a vertical position and hold until a temporary brace is attached

3. The person attending the brace should continue to hold the brace while the frame is being raised to its vertical position.

The person should be prepared to take the weight of the frame to prevent it from falling while it is being finally positioned and plumbed.

Brace can then be nailed off and other braces to be attached as necessary.

Note: It is important to fit sufficient temporary bracing to hold the frame stable and secure.

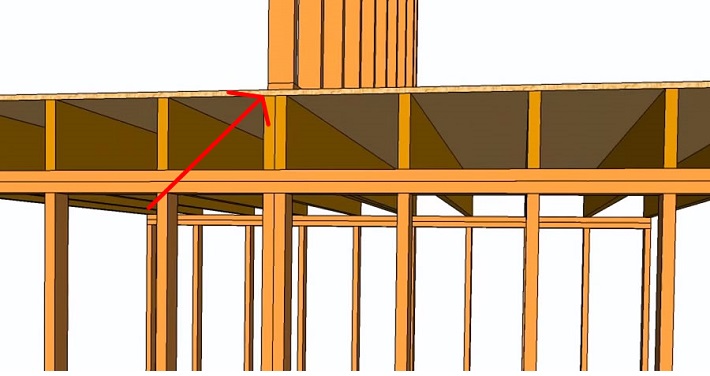

Junction of wall frame sections at top plates

Identified Hazard and Risk Assessment: Persons and unsecured frames falling

Control Measures: All straps, connectors and nailing to the top plate must be carried out using step ladders (or similar) that are self-supporting and not lent against an unsecured frame.

All other nailing at junction of frames can be carried out while working from the floor deck.

Job Step: On completion

Identified Hazard and Risk Assessment: Persons and unsecured frames falling

Control Measures: Check that all framing sections, nail plates, strapping, connectors etc. are nailed off. Also check that all temporary bracing is adequate as required by AS 1684 as well as any additional bracing that may be required for temporary loading that may be applied (i.e.. temporary stacking of roof trusses).

Before this or any SWMS is used it must be checked and adjusted to suit a person’s individual work method, as long as hazards are identified and controlled.

Additional steps will need to be added to suit particular circumstances.

A main function of the SWMS is to identify unsafe conditions and work practices and nominate adequate controls.

Discover more from

Subscribe to get the latest posts sent to your email.