This piping repair method statement defines and guides to painting and coating works for any kind of project or structure. This method statement is applicable to the protective painting and coating for piping and supports at any construction project site. The latest

Read Full Method Statement

This document covers works for the external coating of steel pipes and fitting joints and tests along with a recommendation of generic material types. All the inspection will be performed in accordance with the ITP for field external coating roof steel pipe

Read Full Method Statement

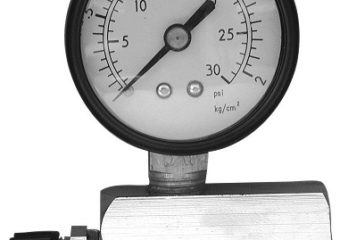

Prior to acceptance and initial operation, all piping installations shall be inspected and pressure tested to determine that the materials, design, fabrication, and installation practices comply with the requirements of this code. Inspection shall consist of visual examination, during or after manufacture,

Read Full Method Statement

Below is the list of tools and equipment that shall be required for installation of Synthetic Natural Gas SNG System. Pipes and Tubes Cutter Arc Welding Machine Oxygen and Acetylene set Calibrated Pressure Gauges Standard Tool Kit for Welder Standard Tool Kit

Read Full Method Statement

Below is a brief method statement for installation & testing of Liquefied Petroleum Gas LPG Piping System including the tank. LPG System shall be installed & tested by specialist supplier approved for the project. Ensure all civil works are completed for the

Read Full Method Statement