Below is given a Safe work method statement for the installation of foundation waterproofing that can be applicable for safe working for any building or project construction. Ensure Material for water proofing material is approved prior to application. Ensure surface preparation is

Read Full Method Statement

The purpose of this method statement / pipe welding procedure is to define and outline proposals for carrying out the welding & installation of MS piping System. Method is applicable to all ERW, Black Steel, Schedule 40, Grade ‘B’ and fittings, in

Read Full Method Statement

Below is a simple to understand safe work method statement for the Demolition of Existing Boundary Wall before starting a new project or renovation works. No. Description of Activity Responsibility 1.0 Ensure all clearances from the concerned Government Department obtain PE/SE 2.0

Read Full Method Statement

Below is complete and simple to follow procedure for Safe Method Statement for Foundation Concreting Installation Works. Ensure all clearances from the concerned Government department obtained. Selected working area should be barricaded to avoid accidents & damages. Ensure suitable access / safe ramps

Read Full Method Statement

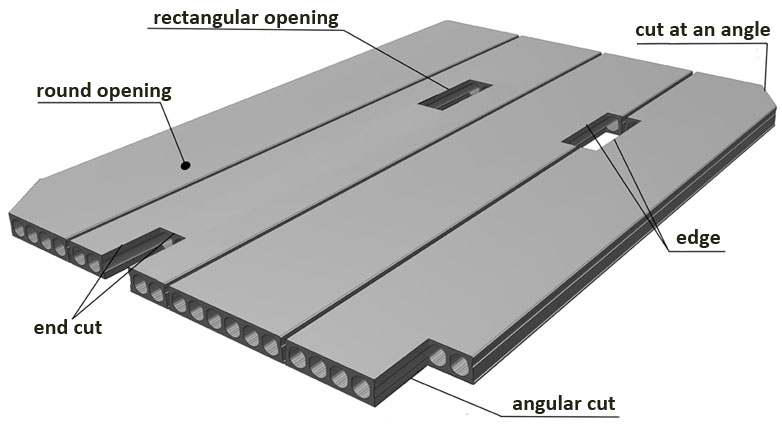

Hollow core slab production and installation method of statement is given below for your use as a sample for different projects. Ensure all clearances from the concerned government department obtained. Selected working area should be barricaded to avoid accidents & damages. Ensure

Read Full Method Statement