This safe work method statement provides the details of the materials, equipment, procedures and relevant documents related to the Rock Blasting activity, including the quality control verification, the measurement verification, and also the safety precautions to be implemented for this work.

The location of the rock blasting works will be limited to selected areas bound within the Right of Way (ROW) as per approval of authorities.

You must follow applicable local regulation for the scope of blasting and mining works, this method statement is for learning and general guidelines only.

Blasting Site Safety Management and Access Control

Safety embankments will be constructed in all locations where there is a need to protect houses or property located outside the rock boundary, downhill from the construction activity and potentially threatened by the works.

The safety embankment will consist of soil and small boulders.

It will be located at the suitable location with the enough height and width.

This will be inline with the instructions and guidelines by regulatory body, clients or consultant as applicable.

Conduct a crack survey to record the present structural condition around the blasting site. The crack survey report will be submitted to the authorities before starting the blasting activities.

Control of Flying Rocks

In the areas where the flying rock needs to be controlled, the charged boulders and benches will be covered using a Wire Mesh, Geo-Textile, Steel Plates, Soil, Used Tires, Sand Bags and Rubber Mats.

Drilling direction will be selected in accordance to avoid Fly Rock flying on to houses or nearby settlements.

Implement a suitable warning procedure for the safety and awareness of residents, workers and any other potentially affected parties.

Equipment’s & Materials

The major equipment for rock drilling, rock blasting and cleaning works includes but not limited to:

- hand drill hammers

- Air Compressor

- Set of Speakers

- Megaphones

- Circuit tester

- Exploder

- Tamping rod

- Siren

- Other minor tools

- Excavator

- Breaker

The major materials used for the rock blasting works include (but are not limited to the following).

Explosive Materials

Water Gel / Dynamite

Electric Detonators

Ammonium Nitrate

Other Materials

Barricade Tapes

Warning Boards

Flags

Tires, steel plates, Geo Textiles, Rubber Mats and Sand bags

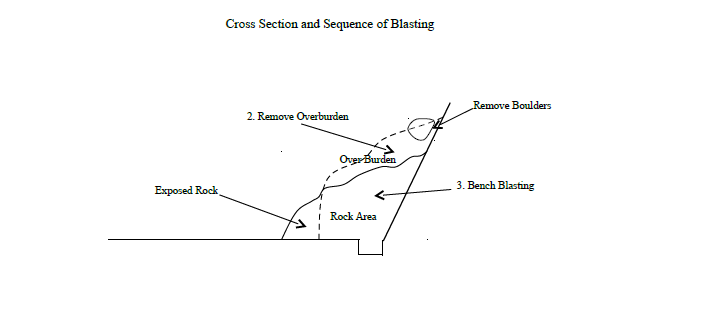

Rock Breaking & Blasting Methodology

The drilling pattern, hole diameter, charge concentration etc., depends on the properties and geological formation of the rock at the location.

Before the commencement of the rock blasting work, the supervisor mining engineer will be notified of the areas where rock will be blasted.

Accordingly, the engineer will inspect the area for approval or confirmation. Drilling will commence only after the completion of rock survey in order to determine the locations and drilling depths required.

Blasting will be executed in accordance with existing local applicable laws and regulations. Relevant permissions will be obtained from the designated authorities before work start.

Explosive user Permit issued by the Controller of Explosives will be available on the site before commencement of rock blasting.

Explosive handling activities will follow according to applicable explosives act of the country. Similarly approval from the authorities will be obtained for storage of explosives.

All blasting operations will be carried out under close supervision of the authorized project site staff.

Only competent persons who have experience and knowledge in handling explosives will be appointed to take charge of the blasting operations at each blasting location.

Explosives will not to be taken to the work site until they are to be used. Firing of the blast will only be carried out in the presence of the in-charge engineer or his representatives. All rock blasting activity shall be conducted in daytime.

The blasting methods are described below.

Boulder Blasting

Boulders, which can’t be moved by Loader or cannot be broken down by giant breaker, will only be blasted. Movable boulders will be collected to a safe place for blasting.

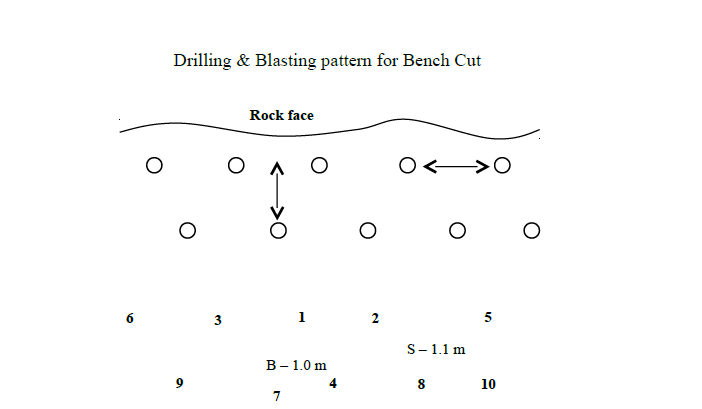

Control Bench Cut Blasting

Drilling: Hammer drill will be used for drilling the “Benches” within the edge. The entire bench depth will be limited to the depth of 3m and will be blasted at one time.

Blast hole diameter: 36 to 40mm

Drilling depth: 1 to 3m

Drilling Plane: Vertical & parallel to CL of the road

Specific Drilling: 2 m / m³

Burden and Spacing: 1.1 to 1.3m

Charging: Specific charge will be 0.29kg / m³ (Dynamite/water gel 125g/hole and 1.2kg). Anticipated charge is a maximum of 15 blast holes per time with 10 delay numbers.

Firing Time and Number of Blasts

Maximum 10 Nos of blast will be fired in a day.

Blasting will be set to lunch time as much as possible.

Only one blasting location will be done in a day.

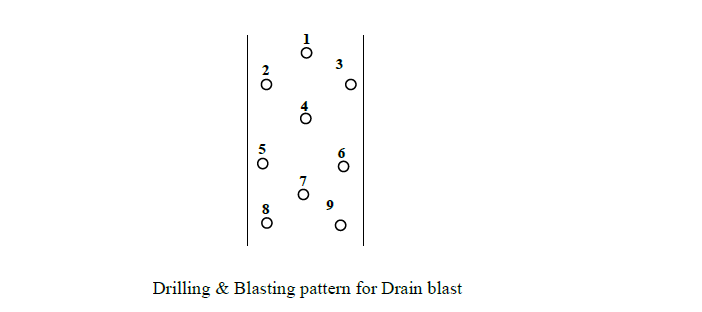

Blasting for Drains

Drilling: Hammer drill will be used for drilling for the “Drains”. The required depth will be decided according to the depth of drain.

Blast hole diameter: 36 to 40mm

Drilling depth: 0.5 m to 1 m

Drilling Plane: Vertical & parallel to CL of the road

Specific Drilling: 3 m / m³

Burden and Spacing: 0.4 m to 1 m

Charging: Specific charge will be 0.33 kg / m³ (Dynamite/water gel 62.5g/hole and 50g). We anticipate charge a maximum of 10 blast holes per time with 10 delay numbers.

Firing Time and Number of Blasts

Maximum 10 Nos of blast will be fired in a day.

Blasting will be set to lunch time as much as possible.

Only one blasting location will be done in a day.

Common way of hole charging and initiation

The Detonator coupled Dynamite/Water Gel piece with a long Ignite Cord or leg wire will be carefully inserted down to the bottom of the hole.

Measured amount of explosive will be then added.

Subsequently, the rest of the hole will gradually be filled with quarry dust (particles not larger than 5mm) and slightly tamped with a lightweight timber or PVC pipe.

Protections will be introduced to control fly rock when required.

All leg wires are series connected and will be fired using an exploder.

Monitoring of Rock Blasting Works

Site monitoring will be carried out by qualified mining engineer to prevent / reduce below effects in every blast.

- Ground vibration level

- Flying rocks

- Air blast sound levels

Several inspections and verifications and regular site visits will be carried out by an expert blasting engineer to ensure that the steps and the procedure are fully complied with this.

After fully cleaning the rock area, a joint survey will be done by all relevant parties to estimate the rock volume.

Then regular survey will be done in every week to check the line and length of the location.

These inspection and measurement results will be used for the payments and analyzing and improving procedures in the company conducting the rock breaking works.

Discover more from

Subscribe to get the latest posts sent to your email.