Purpose of this electrical procedure is to define the step by step method to implement the correct practices for the installation pre-commissioning & commissioning of electrical earthing system.

Guidelines contained herein shall ensure that the job execution complies with the project requirements and serves the intended function to satisfactory level.

The earthing system consists of dedicated earth bus bar for each floor in the electrical room where all the earthing leads of the respective floor equipment are terminated.

Earth bus bars of individual floors shall be connected to the main bus bar in the ground floor which shall drain into the earth pits.

Below is list of necessary tools and equipment for installation and testing of the earthing system.

- Electrician Hand Tools

- Step Ladder

- Multimeter

- Earth Megger

- Portable electric drill

- Calibrated digital earth resistance tester

- Calibrated digital insulation resistance tester

- Helpers Tool Box

- Hammer

- Spirit Level & Water tube

- Hacksaw

- Set of Spanners

Installation of Earthing and Bonding Network

Install equipment earthing conductor for the items below in addition to those required as per technical specification and approved shop drawings:

- Feeders and branch circuits

- Receptacle, lights and switches

- Cable trays/trunking/Flexible raceway runs

- Motors

- Cable Armored and metallic cable glands

- Substations, LV rooms, Plant rooms, etc

- IDF, GSM, MDF, and all other rooms which are part of ELV and LC.

- Equipotential bonding to functional earthing bar.

- Earthing & Bonding for any other equipment or special system as required in the project

Provide separate earthing for MV and Substations, Main Switchboards and Telecommunication equipment as per technical specification and approved shop drawings.

Install separate equipment earthing conductor from the earthing busbar in the switchboard or distribution panel to equipment earthing-bar terminal.

Underground earthing conductors are to be buried below grade unless shown otherwise on approved shop drawings.

A main earth bus bar is to be installed in the electrical room which will be connected to main earth pit.

Main Switchboards, Switchgears and Motor Control Centers Earthing: connect the special earthing lug or busbars inside the cabinet to the main earth copper tape as per technical specification.

All equipment/ panels inside the main electrical room are to be connected to the earth busbar.

The earth connection to various equipment’s to be done using proper nuts, bolts and washers.

For Distribution Boards earthing: connect earthing conductor from the main distribution earth bus bar to an earth connector welded to the cabinet and earthing bushings on the incoming and outgoing feeder conduits.

For Bus-Duct Feeders earthing connect the yellow/green coded earth busbar directly to the earth bus-bar in main switchboard with copper tape or cable as per IFC drawings.

The equipment earthing terminal bars of the normal and essential electrical system panel boards will be bonded together with an insulated continuous copper bonding jumper or refer to manufacturer’s recommendation.

Bond together each metallic raceway, pipe, duct and other metal object entering space under access floors.

Provide earthing and bonding connections for structural metal works like raised floor of electrical equipment’s.

Ensure to provide suitable bonding type for pipe, duct and other services such as water main bond, pipe bond, rwp bond as per approved material submittal and manufacturer’s written instruction.

Provide flexible copper braid bond connections for possibility of expansion joints and also where vibrating equipment is installed.

All joints of cable trays, ladders and trunking shall be bonded for continuity using 6.0 sq.mm Y/G stranded copper cable.

Installation of Earth Rods and Earth Pits

Mark the Earth Rods/Pits as shown on approved drawings.

Provide earthing pit with cover at each rod location.

Install earthing pit top flush with finish grid, as per approved shop drawing.

Check and ensure that the earth pit location does not interfere with any other external services or underground services.

The resistance between the earthing system and absolute earth shall not exceed 10 ohms (for MV & LV) and 20 ohms (for generators), this will be measured in the presence of the consulting engineer or his representative.

Earth electrodes must be driven to a depth in order to achieve the soil resistivity levels below 10 Ohms. A Bore well drilling machine shall be used for this purpose. If necessary boring shall be done to the required depths unless otherwise stated on the approved shop drawings.

Standard ground copper bonded rods should be coupled /tightened to each other using approved couplers.

After positioning the earth rod, the well shall be filled with soil. If the resistance is too high, use approved conductive aggregate.

Grounding system/ network should be connected to the ground electrode by ground continuity conductors or tapes as per approved drawing using the ground rod clamps.

Pre Commissioning Procedure for Earthing System

Ensure that the Earthing System installation is complete and mechanical completion is approved & all comments on the installation are incorporated.

Check and ensure that all types of grounding to the grounding electrodes are as per acceptable codes.

Ensure that no damage has occurred between mechanical completion & pre-commissioning.

Check and ensure proper termination of the earthing cables in the floor bus bar & the main bus bars.

Ensure all contact surfaces of all ground connections are thoroughly cleaned.

Replace damaged cables, if any

Ensure the installation is in line with the approved shop drawings & manufacturer’s recommendations.

Check and ensure that all the earth bars are properly fixed to the wall & are freely accessible.

Ensure the containment for the earth cables are properly supported & the earth cables are properly dressed.

Make sure that all wall / slab penetrations of the cables/trays are sealed with approved fire sealant at each fire barrier penetration.

Commissioning Procedure for Earthing System

Ensure that all the pre commissioning checks are carried out successfully.

Make sure that the earth bars are in level using spirit level.

Check the continuity of the earth cables from the respective equipment to the floor earth bar.

Test the continuity of the earth cables from the respective floor earth bars to the main earth bar of the respective building.

Check the continuity of the earth cables from the respective main earth bar of the building to the earth pits.

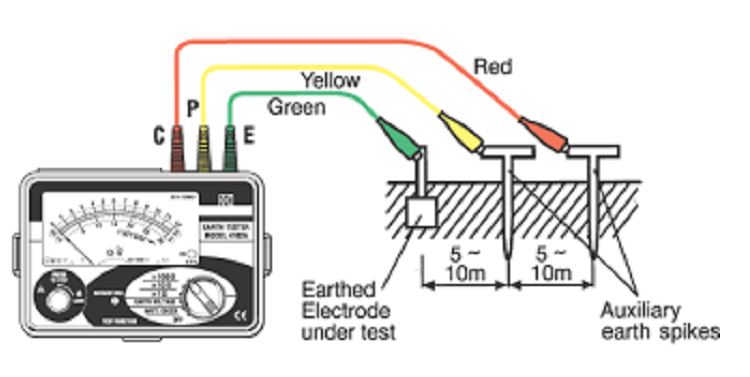

Test the earth resistance values at the earth pits individually & ensure that the value is less than one ohm.

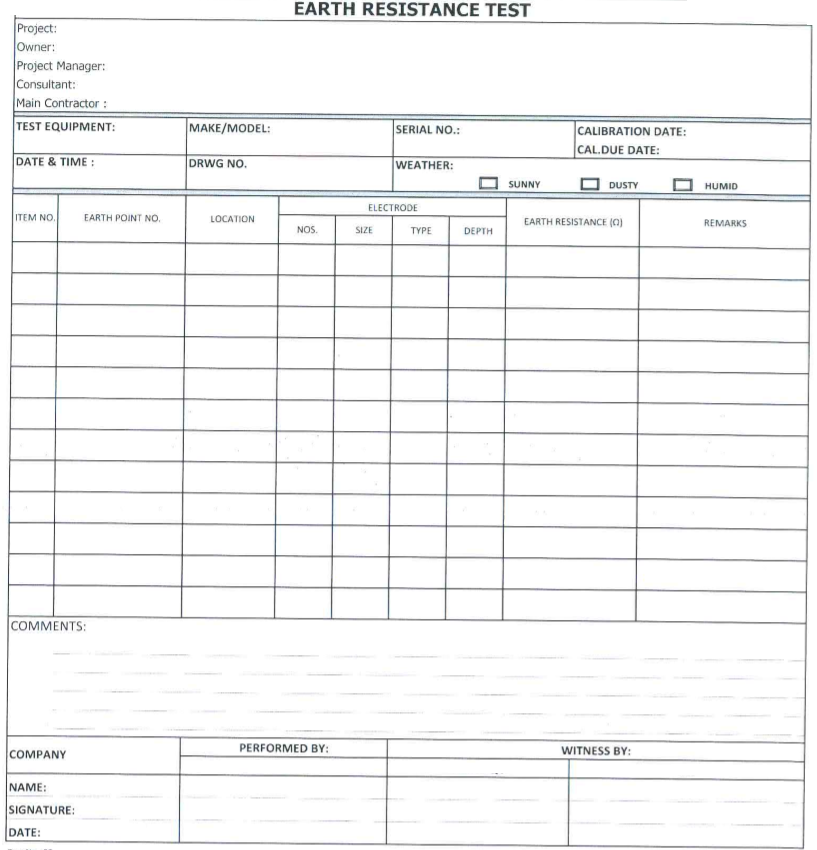

Earth Resistance Testing Checksheet